Fruit Processing Equipment

We supplied fruit Processing line, equipment such as Fruit and Vegetable Washer, Fruit & Vegetable Washer, Brush Roller Washer, Universal Rod Washer, Fruit Pulper, Mango Destoner, Mango Pulper, Coarse Cum Fine Pulper, Pulper Cum finisher, Tomato Crusher, Fruit Mill, Hammer Chopper, Pineapple Corer Sizer, Pineapple Slicer, Inspection Conveyor Merry Go Round, Discharge Conveyor, Empty Feed cans Sterilization Conveyor, Exhauster, Roller Conveyor, Inspection Conveyor 3 Tier, Sorting Conveyor Belt Conveyor, Sterilization conveyor, Bucket Elevator, Flight Elevator, Screw Elevator, Stainless steel tank, Mixing Tank, Tank, Evaporator, Vacuum Pan, Belt Type Blancher, Cooler, Screw Type Blancher, Preheater, Steam Jacketed Kettle, Tube In Tube Pasteuriser, Rotary Scrape Surface Pasteurizer, Shell & Tube Heat Exchanger, Pasteurizer, Retort, Exhauster, Pea Podder, Pulp Filling Machine, Juice Filling Machine, Pouch Packing Machine, Bottle Washer, Two Head Bottle Filler, Single Head Bottle Filler, Lug Off capping Machine, Can Reforming Machinery, Seamer, 1 A DS Seamer, 24 DS Seamer, Food Packaging machine, Crate Washer.

Rotary Fruit & Vegetable Washer

Rotary type with drum suitable for washing fruits / vegetables potatoes, carrots etc through jet water spray

This machine will be adequate to remove dirt, soil, small insects, formed fungus and residues of fertilizers.

Capacity from 500 Kg/Hour To 2000 Kg/Hour for the continuous lines.

Washing system completely manufactured in AISI 304 Stainless Steel

Rotary type with drum suitable for washing fruits / vegetables potatoes, carrots etc through jet water spray

This machine will be adequate to remove dirt, soil, small insects, formed fungus and residues of fertilizers.

Capacity from 500 Kg/Hour To 2000 Kg/Hour for the continuous lines.

Washing system completely manufactured in AISI 304 Stainless Steel

Hot Break System

Hot Break / Cold Break System

Sun Engineers Hot Break & Cold Break System process tomato puree or concentrate guarantying the pectin enzymatic inactivation in the final product.

This process is critical and fundamental in any tomato processing system. The aim is to inactivate the pectin and avoid the syneresis phenomenon in the final product. The Syneresis is the separation of liquids from solids in the tomato paste, caused by the failure to inactivate the enzymes that transform the pectin into serum.

Enzymatic inactivation can be done by two well-known processes: Hot Break & Cold Break. Decision between one or another depends of the final product we want to achieve.

Hot Break is recommended for high viscosity products such as sauces, ketchup, puree and others.

Cold Break is recommended for tomato juice and low viscosity sauces.

The final product is less viscous, with a low-pectin content, excellent organoleptic characteristics and high syneresis level.

The unit consists of:

Tank vertical cylindrical stainless steel complete with accessories

Centrifugal pump for the forced recirculation of the product through the heat exchanger

Heat exchanger that heats and keeps the product within the in activation of enzymes for a specified time.

Series piping for the product, water, steam, condensate, etc., complete with manual and pneumatic valves and accessories.

Structure in galvanized carbon steel Mono pump for extraction of the product with a variable speed motor

Capacity: - Min 500 Kg /Hr Max 10 Ton/Hr

Hot Break / Cold Break System

Sun Engineers Hot Break & Cold Break System process tomato puree or concentrate guarantying the pectin enzymatic inactivation in the final product.

This process is critical and fundamental in any tomato processing system. The aim is to inactivate the pectin and avoid the syneresis phenomenon in the final product. The Syneresis is the separation of liquids from solids in the tomato paste, caused by the failure to inactivate the enzymes that transform the pectin into serum.

Enzymatic inactivation can be done by two well-known processes: Hot Break & Cold Break. Decision between one or another depends of the final product we want to achieve.

Hot Break is recommended for high viscosity products such as sauces, ketchup, puree and others.

Cold Break is recommended for tomato juice and low viscosity sauces.

The final product is less viscous, with a low-pectin content, excellent organoleptic characteristics and high syneresis level.

The unit consists of:

Tank vertical cylindrical stainless steel complete with accessories

Centrifugal pump for the forced recirculation of the product through the heat exchanger

Heat exchanger that heats and keeps the product within the in activation of enzymes for a specified time.

Series piping for the product, water, steam, condensate, etc., complete with manual and pneumatic valves and accessories.

Structure in galvanized carbon steel Mono pump for extraction of the product with a variable speed motor

Capacity: - Min 500 Kg /Hr Max 10 Ton/Hr

Pulper / Destoner

Designed for extracting the pulp of most fruits & vegetables such as mangoes guavas, peaches, tomatoes, bananas, etc.

The unit consists of two brushes and two beaters which give a combined beating and brushing action the unit can also be supplied with four beaters or four brushes depending upon the fruits to be handled.

The gap between the sieve and the brushes, depending upon the fruits to be handled.

The gap between the sieve and the brushes and beaters can be adjusted to suit different types sizes and qualities of products to be pulped.

The sieve is available in perforations of different sizes

The body of the Pulper is made of robust steel structure & is fitted with an easily removable sieve, which is available in perforations of different sizes.

All metal contact parts are of AISI 304 quality stainless steel.

All parts can be easily dismantled & reassembled for facility of inspection, proper washing & cleaning, periodic maintenance.

A compact, sturdy unit which in which the fine Pulper is fitted below the coarse Pulper.

Both the Pulpers are mounted on a robust mild steel / S.S structure

Pulp from the course Pulper is transferred through into the finisher.

Using appropriate sieves, different combinations are possible:

Capacity: Depending upon type, size & quality of product to be pulped.

Designed for extracting the pulp of most fruits & vegetables such as mangoes guavas, peaches, tomatoes, bananas, etc.

The unit consists of two brushes and two beaters which give a combined beating and brushing action the unit can also be supplied with four beaters or four brushes depending upon the fruits to be handled.

The gap between the sieve and the brushes, depending upon the fruits to be handled.

The gap between the sieve and the brushes and beaters can be adjusted to suit different types sizes and qualities of products to be pulped.

The sieve is available in perforations of different sizes

The body of the Pulper is made of robust steel structure & is fitted with an easily removable sieve, which is available in perforations of different sizes.

All metal contact parts are of AISI 304 quality stainless steel.

All parts can be easily dismantled & reassembled for facility of inspection, proper washing & cleaning, periodic maintenance.

A compact, sturdy unit which in which the fine Pulper is fitted below the coarse Pulper.

Both the Pulpers are mounted on a robust mild steel / S.S structure

Pulp from the course Pulper is transferred through into the finisher.

Using appropriate sieves, different combinations are possible:

Capacity: Depending upon type, size & quality of product to be pulped.

Crate Washer

We are manufacture & exporter of High quality Crate Washer that are used for thorough washing the Crates.

Empty crates are turning and convey to crate washer for cleaning.

Spray heads are distributing around: the outside around the crate, upper and lower, front and back, left and right, all have spray nozzles for water spraying.

Cleaning device is closed type.

In front of the water pump has filter device designed and it's for garbage not to absorb into pump and during the cleaning of filter membrane, it's easy to operate.

Spraying time and calculation method for emapty crate inside

Capacity :- 500 / 1000 Crates/hr.

We are manufacture & exporter of High quality Crate Washer that are used for thorough washing the Crates.

Empty crates are turning and convey to crate washer for cleaning.

Spray heads are distributing around: the outside around the crate, upper and lower, front and back, left and right, all have spray nozzles for water spraying.

Cleaning device is closed type.

In front of the water pump has filter device designed and it's for garbage not to absorb into pump and during the cleaning of filter membrane, it's easy to operate.

Spraying time and calculation method for emapty crate inside

Capacity :- 500 / 1000 Crates/hr.

Turbo Refiner

Suitable for the extraction and refining of fruit puree tomato and vegetable.

Shiva Engineers is composed of an extractor and of a refiner, complete with a double horizontal cylindrical body a double motor shaft, a double bearing structure a three phase electric motor, two safety devices and an internal washing device with sprayers with water and steam on two levels.

Shaft Support is precisely machined cast housing fitted with SKF Make Bearing Lubrication to bearing is with grease nipple.

Upper Stage Body of refiner is made of S.S 304 with pulping screen consist of 3 mm perforation outside and 1.5 mm perforation is inside the pulping screen & Lower Stage Body of refiner is made of S.S 304 with pulping screen consist of 1.5 mm perforation outside and 1.2 mm perforation is inside the pulping screen

Rotor is perfectly aligned inside the screen.

Washing can be done in place of body and screen

Rotor is made of S.S 304 blades are fitted in hub S.S Polished

Pulper arrangement to remove hub from shaft easily.

Rotor is supported by SKF make suitable heavy duty ball bearing at two places.

Electrical motor foot mounted is mounted on frame.

Electrical Panel with V.F.D for speed regulation

Frame mild steel duly painted

This extractor is used for the processing of a wide range of product into puree without seeds and skin. It is used for product refining phase.

Suitable for the extraction and refining of fruit puree tomato and vegetable.

Shiva Engineers is composed of an extractor and of a refiner, complete with a double horizontal cylindrical body a double motor shaft, a double bearing structure a three phase electric motor, two safety devices and an internal washing device with sprayers with water and steam on two levels.

Shaft Support is precisely machined cast housing fitted with SKF Make Bearing Lubrication to bearing is with grease nipple.

Upper Stage Body of refiner is made of S.S 304 with pulping screen consist of 3 mm perforation outside and 1.5 mm perforation is inside the pulping screen & Lower Stage Body of refiner is made of S.S 304 with pulping screen consist of 1.5 mm perforation outside and 1.2 mm perforation is inside the pulping screen

Rotor is perfectly aligned inside the screen.

Washing can be done in place of body and screen

Rotor is made of S.S 304 blades are fitted in hub S.S Polished

Pulper arrangement to remove hub from shaft easily.

Rotor is supported by SKF make suitable heavy duty ball bearing at two places.

Electrical motor foot mounted is mounted on frame.

Electrical Panel with V.F.D for speed regulation

Frame mild steel duly painted

This extractor is used for the processing of a wide range of product into puree without seeds and skin. It is used for product refining phase.

Application

• Tomatoes.

• Apples, Pears, Apricots, etc.

• Strawberries, cranberries, raspberries, etc.

• Grapes.

• Bananas and tropical fruits.

• All kind of vegetables.

Capacity :- Min 500 Kg/Hr Max 10 Ton/Hr

Fruit Mill / Hammer Chopper

We manufacture different types of fruit mills, which are made of food grade stainless steel.

These fruit mills are designed to crush the fruits and vegetables to extract juice and pulp.

After the tomatoes, Apple, Guava, Carrot, Papaya have been washed and sorted, selected ones are chopped, in this process the tomatoes are processed into small pieces, resulting in a mixture composed of liquid and solid parts.

Sun Engineers chopping system uses a crushing mill containing a rotor that spins and crushes the tomatoes at high speeds.

The resulting paste is pump able and ready to receive the thermal treatment.

Enzymatic inactivation by a thermal treatment will follow.

Consists of shell body having inside serration.

Rotor is also having outside serration.

Product like Tomato, Guava & papaya is crushed in fruit mill.

To make paste.

The machine runs stability and easy to operate.

After the tomatoes have been washed and sorted, selected ones are chopped, in this process the tomatoes are processed into small pieces, resulting in a mixture composed of liquid and solid parts.

Sun Engineers chopping system uses a crushing mill containing a rotor that spins and crushes the tomatoes at high speeds.

The resulting paste is pump able and ready to receive the thermal treatment.

Enzymatic inactivation by a thermal treatment will follow.

Capacity: - Min 500 Kg /Hr Max 10 Ton/Hr

We manufacture different types of fruit mills, which are made of food grade stainless steel.

These fruit mills are designed to crush the fruits and vegetables to extract juice and pulp.

After the tomatoes, Apple, Guava, Carrot, Papaya have been washed and sorted, selected ones are chopped, in this process the tomatoes are processed into small pieces, resulting in a mixture composed of liquid and solid parts.

Sun Engineers chopping system uses a crushing mill containing a rotor that spins and crushes the tomatoes at high speeds.

The resulting paste is pump able and ready to receive the thermal treatment.

Enzymatic inactivation by a thermal treatment will follow.

Consists of shell body having inside serration.

Rotor is also having outside serration.

Product like Tomato, Guava & papaya is crushed in fruit mill.

To make paste.

The machine runs stability and easy to operate.

After the tomatoes have been washed and sorted, selected ones are chopped, in this process the tomatoes are processed into small pieces, resulting in a mixture composed of liquid and solid parts.

Sun Engineers chopping system uses a crushing mill containing a rotor that spins and crushes the tomatoes at high speeds.

The resulting paste is pump able and ready to receive the thermal treatment.

Enzymatic inactivation by a thermal treatment will follow.

Capacity: - Min 500 Kg /Hr Max 10 Ton/Hr

Steam Jacketed Kettle

Our range of stream jacketed kettle is effective in various food processing applications. These machines are used to heat pulp and juice of fruits and vegetables to a desired temperature.

Our range of stream jacketed kettle is effective in various food processing applications. These machines are used to heat pulp and juice of fruits and vegetables to a desired temperature.

1. Steam Jacketed Kettle (tilting Type)

2. Steam Jacketed Kettle (fixed Type)

3. Fixed Type with Stirrers

Used for Heating of Pulp / Juice to a Desired Temp.

Capacity: 225, 425, 500, 750, 1000 Liters.

Retort

We provide various types of retorts, which are used for sterilizing of cans and bottles before filling up foods or liquid. There is a comprehensive collection of retorts, which are available in various capacities, working specifications and size of crate.

We provide various types of retorts, which are used for sterilizing of cans and bottles before filling up foods or liquid. There is a comprehensive collection of retorts, which are available in various capacities, working specifications and size of crate.

Mixing Tank

We manufacture all types of mixers that are used in mixing pulp and juices of various fruits and vegetables. These mixers are made of food grade materials and are offered in various working specifications. We can also manufacture custom designed mixers.

We manufacture all types of mixers that are used in mixing pulp and juices of various fruits and vegetables. These mixers are made of food grade materials and are offered in various working specifications. We can also manufacture custom designed mixers.

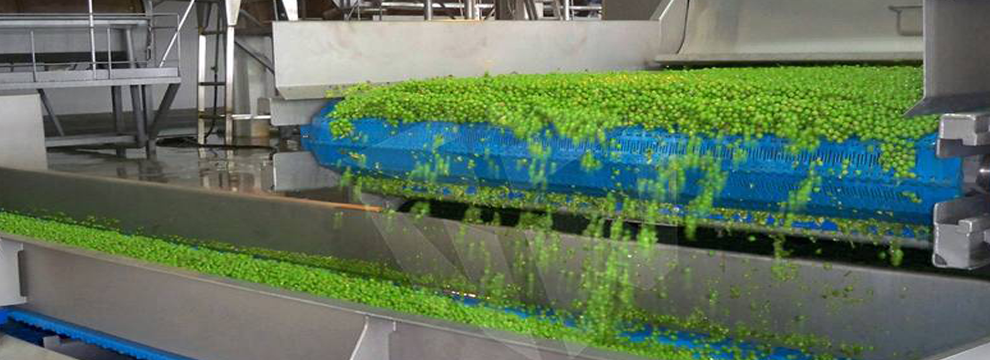

Fruit & Vegetable Washer

We offer complete and continuous washing line for fruits and vegetables to be processed in puree and or juice.

We offer complete and continuous washing line for fruits and vegetables to be processed in puree and or juice.

Capacity from 0.25 mt/hr to 20 mt/hr for the continuous lines.

Washing system completely manufactured in AISI 304 stainless steel and equipped with blower.

Sorting line with belt or rollers equipped with motor variator to adjust the speed.

We also produce batch type washing unit for small production capacity.

The main components of the washer are:

1. S.S Tank

2. P.P/S.S Belt

3. Pump

4. Gearbox & Motor

5. Bearing

6. Special nozzles for fresh water spray

7. Overflow drum

Suitable for through, efficient, washing of most varieties of fruits & vegetables (Mango, Tomato, Ginger Pineapple Apple Citrus Guava etc.)

The fruits & vegetables to be washed are feed to large Stainless Steel tank, where they are soaked in water & subjected to thorough agitation by means of a powerful blower, to loosen dirt, dust & such other foreign particles.

The product is Pushed by water jet then picked up by a stainless steel conveyor/ polyvinyl/ chloride perforated slat conveyor, & subjected to powerful sprays of fresh water for further through cleaning.

Depending upon the types of fruits & vegetables to be washed, the process conditions & through put required, fruit & vegetable washers of different model, designs & materials of construction can be supplied as per specific requirement.

Pulper Cum Finisher

Mango Pulper Cum Finisher:

Mango Pulper Cum Finisher:

Designed for extracting the pulp of most fruits & vegetables such as mangoes, guavas, peaches, tomatoes, bananas, etc.

The Pulper cum finisher is used for extraction of pulp by separating skin and fiber from fruits.

The unit consists of two brushes & two beaters, which give a combined beating, & brushing action.

The unit can also be supplied with four beaters or four brushes, depending upon the fruits to be handled.

The gap between the sieve & the brushes & beaters can be adjusted to suit different types, sizes & qualities of products to be pulped.

The sieve is available in perforations of different sizes

The workings of the machine depend upon type, size and quality of the product to be pulped.

Capacity: - Min 500 Kg /Hr Max 10 Ton

Conveyor / Elevator

We offer a complete range of conveyors, which are suitable for conveying or inspecting of fruits and vegetables like mango, guavas, tomatoes etc. Available in various working specifications, these conveyors can also be customized as per the requirement of clients. In this range, we offer:

INSPECTION / SORTING BELT CONVEYORS

Suitable for inspection and preparation of fruits and vegetables like mangoes, tomatoes, guavas etc. before being pulped. It consists of a food quality conveyor belt which is divided lengthwise into three parallel lanes.

Worker standing on either side of the conveyor manually pick and dress the fruits and deposit the prepared fruits on to the central lane, from where they are conveyed to the discharge chute.

Aluminium / Stainless steel side guides prevent the product from going sideways.

Aluminium pockets are provided along the length of the conveyor table on both slide for convenient disposal of waste material on the return side of the conveyor belt and is discharged through a suitable chute for collection and final disposal.

The return side of the conveyor belt is cleaned by means of a suitable rubber scrapper, followed by brushing unit and water spray.

The feed and discharge hoppers of this conveyor are in AISI 304 quality stainless steel.

Size available in standard size of 5 10 12 Meters distance between centers of driving and driven pulleys depending upon requirement. Other sizes can also be offered

Capacity depending upon size of unit operation to be carried out number of workers and efficiency of workers.

ROLLER INSPECTION CONVEYOR

Designed for continuous inspection picking and sorting of apples peaches citrus fruits tomatoes and such other fruits and vegetables the fruits are fed to the roller inspection conveyor on which they are rotated practically around for inspection and sorting and then conveyed to the discharge end

FLIGHT / BUCKET ELEVATOR

Flight /Bucket Elevator manufactures for Plastic, Modular Belt, PVC Belt, Stainless Steel handling system for hygienic handling of food products and other agro products.

We have hi quality buckets. We have a complete range of plastic and nylon modular belts for various conveyor applications and a complete manufacturing facility for moving and lifting material our equipment’s are trustable for continuous production lines in food industries.

SCREW CONVEYOR

Screw Conveyor designs and manufactures equipment for various industries such as Food Processing, Pharmaceuticals, Chemical industries, Packaging industries, salt, cement, coal, bio-mass, agriculture and other industries where there is a need for industrial duty equipment to convey free flowing bulk materials.

Screw conveyor is use for transfer the material like Fruit Waste, Sugar, Powder or grains form.

U type trough & flight is screw type, top covered, both end sealing type for prevent dust leakages.

Features

Capacity: Depending upon sizes of unit operation to be carried

Available in standard sizes of 3-15 meters distance between centers of driving and driving pulley

1. Inspection Conveyor Merry Go Round

2. Discharge Conveyor

3. Sterilization Conveyor

4. Roller Conveyor

5. 3 Tier Inspection Conveyor

6. Sorting Conveyor

7. Belt Conveyor

8. Packing Conveyor

9. Screw Conveyor

Pineapple Peeling Machine

For removing edible portion of fruit remaining on the peels after coring & sizing.

Working

The pineapples are fed manually in the feed tray with fruit side up, which are picked up by a spiked rotating drum. There are steel knives that are used for deep cutting.

Thereafter, the pineapples move to v-shaped stripping knives, which can be adjusted as per requisite cutting depth.

These v-shaped knifes separate fruit chunks and pieces.

The bottom of v-shaped knifes strips the remaining fruit.

After that, the peels pass over a grating which dislodges them from the spikes.

Capacity: Peels of up to 2000 pineapple per hour

Electric Power: 1 HP ( 0.75 KW )

Rotary type with drum suitable for washing fruits / vegetables potatoes, carrots etc through jet water spray

This machine will be adequate to remove dirt, soil, small insects, formed fungus and residues of fertilizers.

Capacity from 500 Kg/Hour To 2000 Kg/Hour for the continuous lines.

Washing system completely manufactured in AISI 304 Stainless Steel

Rotary type with drum suitable for washing fruits / vegetables potatoes, carrots etc through jet water spray

This machine will be adequate to remove dirt, soil, small insects, formed fungus and residues of fertilizers.

Capacity from 500 Kg/Hour To 2000 Kg/Hour for the continuous lines.

Washing system completely manufactured in AISI 304 Stainless Steel Hot Break / Cold Break System

Sun Engineers Hot Break & Cold Break System process tomato puree or concentrate guarantying the pectin enzymatic inactivation in the final product.

This process is critical and fundamental in any tomato processing system. The aim is to inactivate the pectin and avoid the syneresis phenomenon in the final product. The Syneresis is the separation of liquids from solids in the tomato paste, caused by the failure to inactivate the enzymes that transform the pectin into serum.

Enzymatic inactivation can be done by two well-known processes: Hot Break & Cold Break. Decision between one or another depends of the final product we want to achieve.

Hot Break is recommended for high viscosity products such as sauces, ketchup, puree and others.

Cold Break is recommended for tomato juice and low viscosity sauces.

The final product is less viscous, with a low-pectin content, excellent organoleptic characteristics and high syneresis level.

The unit consists of:

Tank vertical cylindrical stainless steel complete with accessories

Centrifugal pump for the forced recirculation of the product through the heat exchanger

Heat exchanger that heats and keeps the product within the in activation of enzymes for a specified time.

Series piping for the product, water, steam, condensate, etc., complete with manual and pneumatic valves and accessories.

Structure in galvanized carbon steel Mono pump for extraction of the product with a variable speed motor

Capacity: - Min 500 Kg /Hr Max 10 Ton/Hr

Hot Break / Cold Break System

Sun Engineers Hot Break & Cold Break System process tomato puree or concentrate guarantying the pectin enzymatic inactivation in the final product.

This process is critical and fundamental in any tomato processing system. The aim is to inactivate the pectin and avoid the syneresis phenomenon in the final product. The Syneresis is the separation of liquids from solids in the tomato paste, caused by the failure to inactivate the enzymes that transform the pectin into serum.

Enzymatic inactivation can be done by two well-known processes: Hot Break & Cold Break. Decision between one or another depends of the final product we want to achieve.

Hot Break is recommended for high viscosity products such as sauces, ketchup, puree and others.

Cold Break is recommended for tomato juice and low viscosity sauces.

The final product is less viscous, with a low-pectin content, excellent organoleptic characteristics and high syneresis level.

The unit consists of:

Tank vertical cylindrical stainless steel complete with accessories

Centrifugal pump for the forced recirculation of the product through the heat exchanger

Heat exchanger that heats and keeps the product within the in activation of enzymes for a specified time.

Series piping for the product, water, steam, condensate, etc., complete with manual and pneumatic valves and accessories.

Structure in galvanized carbon steel Mono pump for extraction of the product with a variable speed motor

Capacity: - Min 500 Kg /Hr Max 10 Ton/Hr  Designed for extracting the pulp of most fruits & vegetables such as mangoes guavas, peaches, tomatoes, bananas, etc.

The unit consists of two brushes and two beaters which give a combined beating and brushing action the unit can also be supplied with four beaters or four brushes depending upon the fruits to be handled.

The gap between the sieve and the brushes, depending upon the fruits to be handled.

The gap between the sieve and the brushes and beaters can be adjusted to suit different types sizes and qualities of products to be pulped.

The sieve is available in perforations of different sizes

The body of the Pulper is made of robust steel structure & is fitted with an easily removable sieve, which is available in perforations of different sizes.

All metal contact parts are of AISI 304 quality stainless steel.

All parts can be easily dismantled & reassembled for facility of inspection, proper washing & cleaning, periodic maintenance.

A compact, sturdy unit which in which the fine Pulper is fitted below the coarse Pulper.

Both the Pulpers are mounted on a robust mild steel / S.S structure

Pulp from the course Pulper is transferred through into the finisher.

Using appropriate sieves, different combinations are possible:

Capacity: Depending upon type, size & quality of product to be pulped.

Designed for extracting the pulp of most fruits & vegetables such as mangoes guavas, peaches, tomatoes, bananas, etc.

The unit consists of two brushes and two beaters which give a combined beating and brushing action the unit can also be supplied with four beaters or four brushes depending upon the fruits to be handled.

The gap between the sieve and the brushes, depending upon the fruits to be handled.

The gap between the sieve and the brushes and beaters can be adjusted to suit different types sizes and qualities of products to be pulped.

The sieve is available in perforations of different sizes

The body of the Pulper is made of robust steel structure & is fitted with an easily removable sieve, which is available in perforations of different sizes.

All metal contact parts are of AISI 304 quality stainless steel.

All parts can be easily dismantled & reassembled for facility of inspection, proper washing & cleaning, periodic maintenance.

A compact, sturdy unit which in which the fine Pulper is fitted below the coarse Pulper.

Both the Pulpers are mounted on a robust mild steel / S.S structure

Pulp from the course Pulper is transferred through into the finisher.

Using appropriate sieves, different combinations are possible:

Capacity: Depending upon type, size & quality of product to be pulped. We are manufacture & exporter of High quality Crate Washer that are used for thorough washing the Crates.

Empty crates are turning and convey to crate washer for cleaning.

Spray heads are distributing around: the outside around the crate, upper and lower, front and back, left and right, all have spray nozzles for water spraying.

Cleaning device is closed type.

In front of the water pump has filter device designed and it's for garbage not to absorb into pump and during the cleaning of filter membrane, it's easy to operate.

Spraying time and calculation method for emapty crate inside

Capacity :- 500 / 1000 Crates/hr.

We are manufacture & exporter of High quality Crate Washer that are used for thorough washing the Crates.

Empty crates are turning and convey to crate washer for cleaning.

Spray heads are distributing around: the outside around the crate, upper and lower, front and back, left and right, all have spray nozzles for water spraying.

Cleaning device is closed type.

In front of the water pump has filter device designed and it's for garbage not to absorb into pump and during the cleaning of filter membrane, it's easy to operate.

Spraying time and calculation method for emapty crate inside

Capacity :- 500 / 1000 Crates/hr. Suitable for the extraction and refining of fruit puree tomato and vegetable.

Shiva Engineers is composed of an extractor and of a refiner, complete with a double horizontal cylindrical body a double motor shaft, a double bearing structure a three phase electric motor, two safety devices and an internal washing device with sprayers with water and steam on two levels.

Shaft Support is precisely machined cast housing fitted with SKF Make Bearing Lubrication to bearing is with grease nipple.

Upper Stage Body of refiner is made of S.S 304 with pulping screen consist of 3 mm perforation outside and 1.5 mm perforation is inside the pulping screen & Lower Stage Body of refiner is made of S.S 304 with pulping screen consist of 1.5 mm perforation outside and 1.2 mm perforation is inside the pulping screen

Rotor is perfectly aligned inside the screen.

Washing can be done in place of body and screen

Rotor is made of S.S 304 blades are fitted in hub S.S Polished

Pulper arrangement to remove hub from shaft easily.

Rotor is supported by SKF make suitable heavy duty ball bearing at two places.

Electrical motor foot mounted is mounted on frame.

Electrical Panel with V.F.D for speed regulation

Frame mild steel duly painted

This extractor is used for the processing of a wide range of product into puree without seeds and skin. It is used for product refining phase.

Suitable for the extraction and refining of fruit puree tomato and vegetable.

Shiva Engineers is composed of an extractor and of a refiner, complete with a double horizontal cylindrical body a double motor shaft, a double bearing structure a three phase electric motor, two safety devices and an internal washing device with sprayers with water and steam on two levels.

Shaft Support is precisely machined cast housing fitted with SKF Make Bearing Lubrication to bearing is with grease nipple.

Upper Stage Body of refiner is made of S.S 304 with pulping screen consist of 3 mm perforation outside and 1.5 mm perforation is inside the pulping screen & Lower Stage Body of refiner is made of S.S 304 with pulping screen consist of 1.5 mm perforation outside and 1.2 mm perforation is inside the pulping screen

Rotor is perfectly aligned inside the screen.

Washing can be done in place of body and screen

Rotor is made of S.S 304 blades are fitted in hub S.S Polished

Pulper arrangement to remove hub from shaft easily.

Rotor is supported by SKF make suitable heavy duty ball bearing at two places.

Electrical motor foot mounted is mounted on frame.

Electrical Panel with V.F.D for speed regulation

Frame mild steel duly painted

This extractor is used for the processing of a wide range of product into puree without seeds and skin. It is used for product refining phase. We manufacture different types of fruit mills, which are made of food grade stainless steel.

These fruit mills are designed to crush the fruits and vegetables to extract juice and pulp.

After the tomatoes, Apple, Guava, Carrot, Papaya have been washed and sorted, selected ones are chopped, in this process the tomatoes are processed into small pieces, resulting in a mixture composed of liquid and solid parts.

Sun Engineers chopping system uses a crushing mill containing a rotor that spins and crushes the tomatoes at high speeds.

The resulting paste is pump able and ready to receive the thermal treatment.

Enzymatic inactivation by a thermal treatment will follow.

Consists of shell body having inside serration.

Rotor is also having outside serration.

Product like Tomato, Guava & papaya is crushed in fruit mill.

To make paste.

The machine runs stability and easy to operate.

After the tomatoes have been washed and sorted, selected ones are chopped, in this process the tomatoes are processed into small pieces, resulting in a mixture composed of liquid and solid parts.

Sun Engineers chopping system uses a crushing mill containing a rotor that spins and crushes the tomatoes at high speeds.

The resulting paste is pump able and ready to receive the thermal treatment.

Enzymatic inactivation by a thermal treatment will follow.

Capacity: - Min 500 Kg /Hr Max 10 Ton/Hr

We manufacture different types of fruit mills, which are made of food grade stainless steel.

These fruit mills are designed to crush the fruits and vegetables to extract juice and pulp.

After the tomatoes, Apple, Guava, Carrot, Papaya have been washed and sorted, selected ones are chopped, in this process the tomatoes are processed into small pieces, resulting in a mixture composed of liquid and solid parts.

Sun Engineers chopping system uses a crushing mill containing a rotor that spins and crushes the tomatoes at high speeds.

The resulting paste is pump able and ready to receive the thermal treatment.

Enzymatic inactivation by a thermal treatment will follow.

Consists of shell body having inside serration.

Rotor is also having outside serration.

Product like Tomato, Guava & papaya is crushed in fruit mill.

To make paste.

The machine runs stability and easy to operate.

After the tomatoes have been washed and sorted, selected ones are chopped, in this process the tomatoes are processed into small pieces, resulting in a mixture composed of liquid and solid parts.

Sun Engineers chopping system uses a crushing mill containing a rotor that spins and crushes the tomatoes at high speeds.

The resulting paste is pump able and ready to receive the thermal treatment.

Enzymatic inactivation by a thermal treatment will follow.

Capacity: - Min 500 Kg /Hr Max 10 Ton/Hr  Our range of stream jacketed kettle is effective in various food processing applications. These machines are used to heat pulp and juice of fruits and vegetables to a desired temperature.

Our range of stream jacketed kettle is effective in various food processing applications. These machines are used to heat pulp and juice of fruits and vegetables to a desired temperature. We provide various types of retorts, which are used for sterilizing of cans and bottles before filling up foods or liquid. There is a comprehensive collection of retorts, which are available in various capacities, working specifications and size of crate.

We provide various types of retorts, which are used for sterilizing of cans and bottles before filling up foods or liquid. There is a comprehensive collection of retorts, which are available in various capacities, working specifications and size of crate. We manufacture all types of mixers that are used in mixing pulp and juices of various fruits and vegetables. These mixers are made of food grade materials and are offered in various working specifications. We can also manufacture custom designed mixers.

We manufacture all types of mixers that are used in mixing pulp and juices of various fruits and vegetables. These mixers are made of food grade materials and are offered in various working specifications. We can also manufacture custom designed mixers. We offer complete and continuous washing line for fruits and vegetables to be processed in puree and or juice.

We offer complete and continuous washing line for fruits and vegetables to be processed in puree and or juice. Mango Pulper Cum Finisher:

Mango Pulper Cum Finisher: